Johannesen Kran & Maskintransport has had a unique job in connection with the metro construction in Copenhagen; a load-bearing ceiling structure had to be raised the decisive 10 mm, so that old beams could come out and new ones in. But how do you do that when the building was both old and crooked? The solution was a complete package from Fyns Kran Udstyr, which was used to create the necessary space for replacing the supporting beams.

Come with us below the main railway station in Copenhagen where the equipment from Fyns Kran Udstyr is used:

Johannesen Kran- og Maskintransport has had a unique and exciting job this year. In collaboration with Aarsleff Rail, they had to solve a very special job for Banedanmark. In connection with the metro construction in Copenhagen, where Johannesen Kran- og Maskintransport had previously solved many crane and lifting jobs on the construction site by the metro, the company had to help replace 27-metre load-bearing ceiling beams in the old construction under the Central Station, used to form the framework for a new underground passage from a new metro station to copenhagens Cetrail Station: Hovedbanegården. Due to previous damage, the beams had to be replaced as the current construction was too weak.

While the project was on the drawing board, Banedanmark and Aarsleff Rail contacted Johannesen Kran and Maskintransport to hear about possible solutions to the job of replacing the supporting ceiling beams.

To secure the building against collapse during the replacement, the idea was to use hydraulic jacks. Peter Rosenbäck from Johannesen Kran og Maskintransport was interested in a complete solution for this unique project. He chose to contact Fyns Kran Udstyr, who could both advise and at the same time also supply the right products to realize the project.

The existing 27 meter old wooden beams from before the 20th century were a load-bearing part of the ceiling structure in the basement, and in order for the replacement to be carried out safely, the structure was supported by 12 meter long steel beams while the carpentry work was carried out until the new beams could again support the construction. The steel beam was carried by 'soldiers' under which DK Jacks were placed in two separate sections with 7 DK Hydraulic Jacks in each. It was therefore DK Jacks who lifted the load and raised the ceiling construction the crucial 10 mm, so that the old beams could be removed and the new beams inserted.

The solution with DK Jacks was chosen to be able to carry out the replacement in the very tight space. The alternative was simply not an option, the basement, as the space was simply too tight. When it was necessary to find the right equipment for the job, where the space was so tight, Peter Rosenbäck suggested using the jack DK Jack, developed by Fyns Kran Udstyr. Each DK Jack has an individual lifting capacity of 10 tonnes, and it is not just the outer parts of a DK Jack that consist of quality parts. The inner part of a DK Jack has a hydraulic cylinder produced by Dutch manfacturer Holmatro.

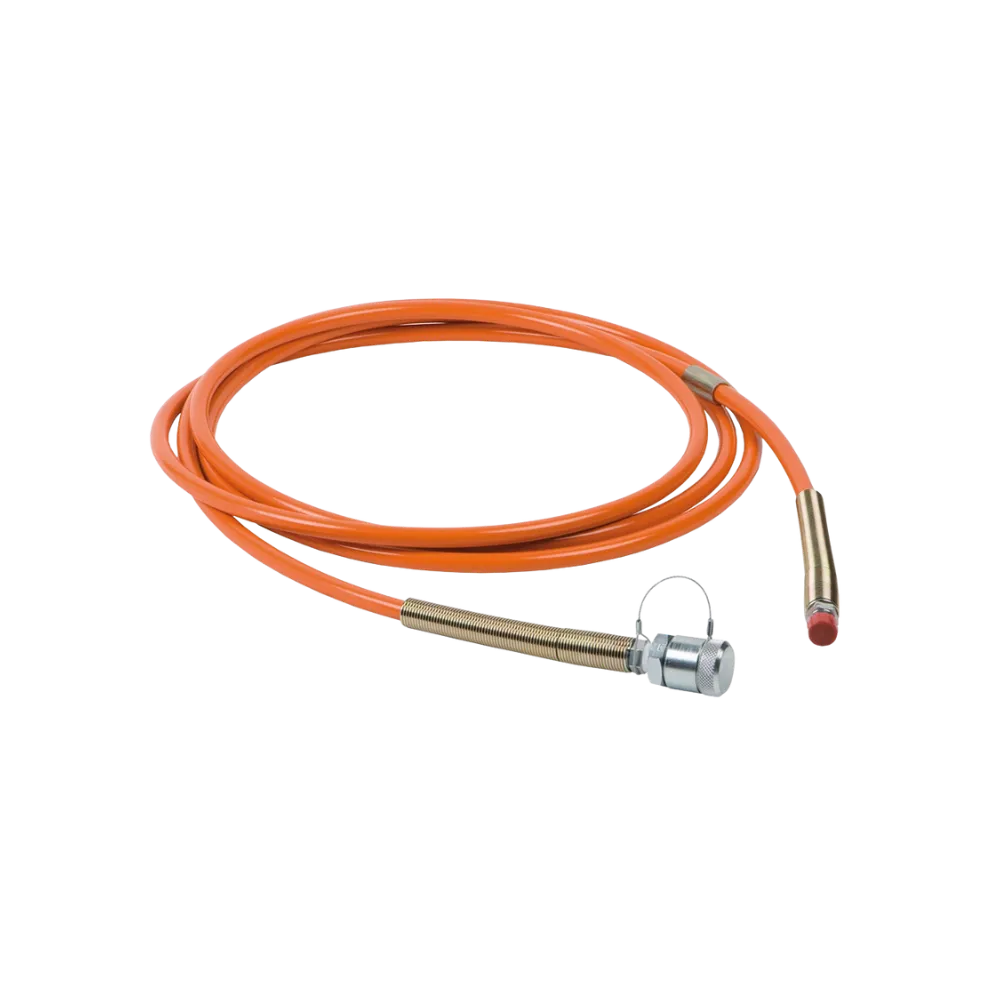

The two 'stations' with seven hydraulic DK Jacks each could be controlled via the two Holmatro flow panels, where the pressure is supplied by a Holmatro electric pump connected to each flow panel. In the configuration that Peter Rosenbäck from Johannesen Kran og Maskintransport chose, it was possible to set 6 individual parameters.

Peter Rosenbäck states: "There is not much in the old building that is completely straight, so the total of 12 adjustment points had to be lifted differently in order for everything to be completely straight. It was all adjusted via the flow panels from Holmatro, and the pressure on the total of 12 outlets could be read on the individual pressure gauges. And the 2 jacks at each end were put on a double hose, and the total of 4 jacks were therefore only controlled from 2 outlets.”

The two complete sets of DK Jack's were delivered in boxes with wheels, so that the two complete sets could be easily transported to and from the job site.

Johannesen Kran og Maskintransport did not hesitate to buy such a large solution with DK Jack products. There were many scenarios where the solution with DK Jack could be particularly useful due to the great flexibility. At the same time, it was a good tool for machine moving jobs, where the low insertion height combined with a very high lifting height was extremely useful.

Find the products in the different product categories:

Get the same complete package.